16706/P0322/000802 - Engine Speed Sensor (G28): No Signal

Possible Symptoms

Engine shuts off

Engine doesn't start

Tachometer / Rev Counter inoperative

Glow Plug Indicator Lamp (K29) flashes

Possible Causes

Engine Speed Sensor (G28) loose

Engine Speed Sensor (G28) faulty

Possible Solutions

Check Engine Speed Sensor (G28)

Special Notes

The Engine Speed Sensor (G28) is also used as a reference sensor for the crankshaft position.

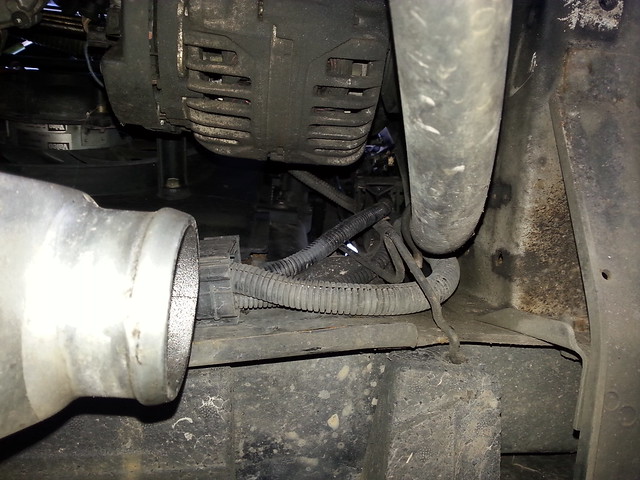

Check the wiring to/from the sensor and engine control module to rule out harness and module damage due to engine oil or coolant from a failed sensor or tensioner.

Possible Symptoms

Engine shuts off

Engine doesn't start

Tachometer / Rev Counter inoperative

Glow Plug Indicator Lamp (K29) flashes

Possible Causes

Engine Speed Sensor (G28) loose

Engine Speed Sensor (G28) faulty

Possible Solutions

Check Engine Speed Sensor (G28)

Special Notes

The Engine Speed Sensor (G28) is also used as a reference sensor for the crankshaft position.

Check the wiring to/from the sensor and engine control module to rule out harness and module damage due to engine oil or coolant from a failed sensor or tensioner.

Comment